IMS / Quality Certification

Improve QEHS and market performance

What's the need?

You Should Know

Organizations all over the world are increasingly concerned to improve their QEHS and market performance in sustainable manner. Accordingly there is a great movement in institutionalizing a structured, systematic and documented management systems approach to achieve the above objective in an auditable manner at enterprise level.

What Organizations Do?

Adopt & Manage

However, traditionally organizations of all kinds have adopted different management systems (i.e. QMS: ISO 9001, EMS: ISO 14001, OHSMS: OHSAS 45001, SA 8000) at a different period of the times in succession based on ISO versions of management systems.

Difficulties On The Way

While implementing and maintaining these respective management systems organizations experience a good degree of difficulty on account of following:

- Multiple/ overlapping organizations responsibilities to manage different management systems

- Multiple policy statements

- Multiple management systems documentation (Apex or Systems Manuals)

- Multiple operational control procedures in varying formats

- Multiple task of record maintenance under each system

- Multiple cadres of internal auditors and overlapping audit schedules

- Multiple and frequent audits by external agencies

- Overlapping of resources

- Inconsistency/ multiple instructions at shop floor levels

- Increased cost due to overlapping of efforts/ audits by external agency

- Multi-focused/multi coordinated efforts

- Multiple internal communications

Accordingly all kinds of organizations have started pursuing the approach towards development and maintenance of unified management systems to address concurrently the confronting quality, production, environment, health & safety, marketing issues.

Principle of IMS

These management systems are termed as “Integrated Management Systems” and follow the following basic management systems principles.

1. Policy

2. Planning

3. Implementation & operation

4. Continual Improvement

5. Checking & corrective action

6. Management review

7. Reporting

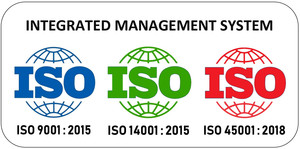

While developing these IMS, it is ensured that it also meets the requirements of the following ISO specifications to demonstrate conformity to stake holders:

01

ISO 9001:2015

02

ISO 14001:2015

03

ISO 45001:2018

In addition to above, a typical IMS also take into account the specific organizational needs and accordingly the PDCA structure is defined. Such a system results in a number of organizational benefits and optimal utilization of its human, financial & technical resources in objective manner. Apart from this, the following benefits are experienced by IMS organizations.

Benefits of IMS

In addition to the following benefits, IMS brings a good amount of consistency in organizational resources and thus providing more opportunity for innovation and growth.

BenefitS

- Unified Policy statement

- Unified/ single management systems manual addressing the requirement of ISO 9001, ISO 14001 and OH&S 45001/ SA 8000 in addition to organizational needs.

- Unified/ single operational control procedures to cover all situations which can result in deviation from the above policy statement.

- A unified master list of objectives & targets and management programmes.

- An integrated auditing competence (Internal Auditors equipped with knowledge in competence to perform combine audits i.e. all management systems at a time)

- Combined certification and audit programme from a single certification agency.

Typical Methodology for Design, Implementation and Certification/ Maintenance of IMS

Certification, But How?

(CERTIFICATION W.R.T. QEHS MANAGEMENT SYSTEMS)The typical road map for design, implementation and maintenance of integrated management systems includes following steps:

- DESIGN STAGE

- IMPLEMENTATION STAGE

- CERTIFICATION STAGE

- OUR APPROACH

Let’s know more about each stage

1. Design Stage

- Appreciation training to top/ senior/ middle management on IMS

- Appointment of management representative and steering group

- Development of combined QEHS policy

- Development of combined IMS manual

- Development of register of applicable legislation.

- Development of IMS operational procedures manual

- Development of QEHS objectives and management programmes.

- Development of register of EHS aspects/ hazards

Note for “Development of combined IMS manual”: This shall include all the PDCA mechanism including commitment, customer focus, roles, responsibilities & resource management, product/ services design, development & realization, purchasing, analysis of data, training, awareness and competence, document control, emergency response preparedness, vendors/ contractors control, community relation, monitoring and measurement, internal & external communication, document control, internal audits and management review, bench marking, amongst other management aspects)

2. Implementation Stage

- IMS training to all personnel including shop floor management and contractual workforce

- Internal auditors training as per ISO 19011:2002

- Internal IMS audit

- Internal IMS management review

3. Certification Stage

- Selection of certification agency

- Pre assessment

- Main assessment

- Final certification

Finally Our Approach

Using a combined or integrated approach across all audit criteria, ANM will help you gain efficiencies that may not be achieved by auditing individual management systems. Integrated management systems can be implemented by organizations in any sector and of any size. Organizations consider this step to lower costs and simplify their maturing management systems. ANM offers two ways for you to combine audits to multiple standards:

- A combined audit occurs when management system audits related to different audit criteria (standards) are conducted simultaneously.

- An integrated audit is the assessment of an integrated management system, which fully or partially integrates the requirements of different audit criteria with a single set of documentation, policies, procedures and processes.

Many organizations choose to combine audits to ISO 9001 and ISO 14001 and OH&S 45001. Many other combinations are possible. A combined or integrated audit can bring many benefits to your organization, such as: lower certification costs, fewer interruptions to the organization, reduced documentation, streamlined processes, and more consistent objectives across multiple systems.